Most teams know they should cycle count. Fewer teams actually do it consistently. The problem is rarely motivation - it is the lack of a repeatable schedule that survives a busy Monday morning.

This guide gives you the missing piece: a practical framework for deciding what to count, how often, who does it, and what numbers to watch. If you already know why cycle counting beats a painful annual shutdown, skip ahead. If not, our introduction to cycle counting covers the case for making the switch.

Why frequency matters more than coverage

A common mistake is trying to count everything equally. That feels fair, but it wastes effort. A $2,000 power tool that sells daily deserves more attention than a $0.50 fastener you reorder twice a year.

The goal is not to count every SKU every week. The goal is to catch errors before they cost you money. That means counting high-impact items frequently and low-impact items on a longer cycle. The industry target for inventory record accuracy (IRA) is 97% or higher, and the best-run warehouses push above 99%.

An annual stock-take is a crash diet: painful, disruptive, and the results fade fast. Cycle counting is a healthy routine: small, consistent effort that compounds into lasting accuracy.

Step 1: classify SKUs with ABC analysis

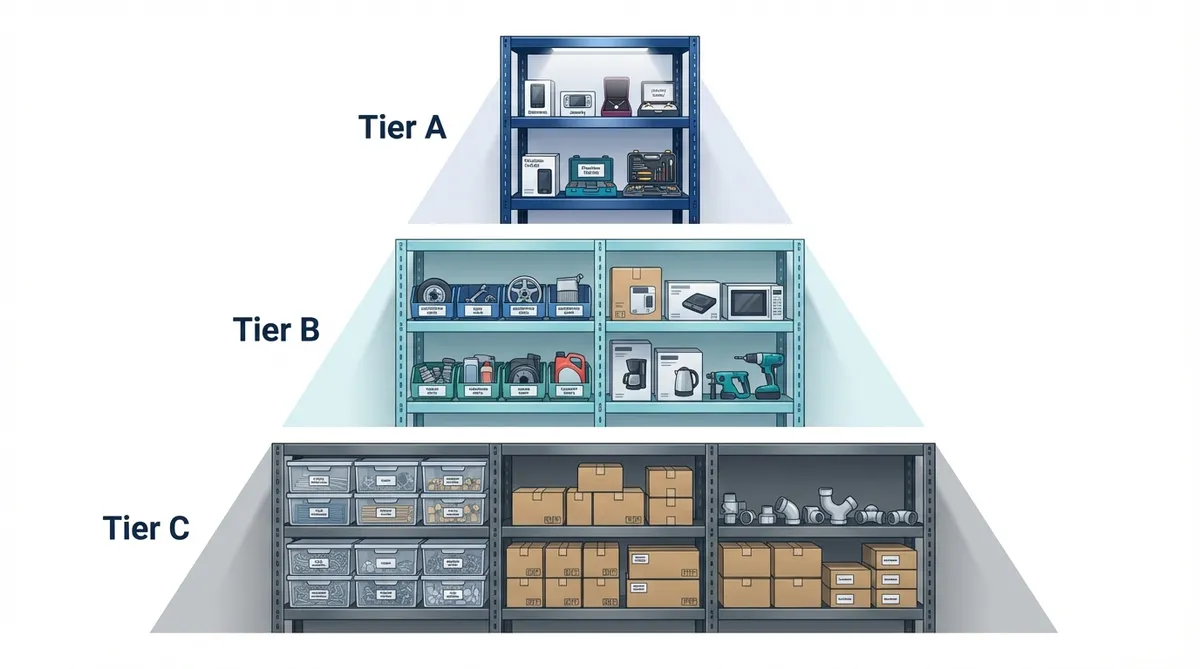

ABC analysis groups your inventory by value impact. The Pareto principle (roughly 80/20) is the starting point, but your exact split will depend on your catalog.

Roughly 20% of SKUs driving about 80% of your revenue or usage value. These are your fast movers and high-value products. Errors here directly hit sales and cash flow.

Around 30% of SKUs contributing about 15% of value. Important, but a single miscount rarely triggers a crisis.

The remaining 50% of SKUs, often representing only 5% of total value. Low risk individually, but they still need periodic verification.

To build your ABC list, export your SKUs with the last 90 days of sales or usage value. Sort descending by value. Walk down the list and draw two lines: the first when cumulative value hits roughly 80% (that is your A group), the second at roughly 95% (that is your B group). Everything below is C.

If you want a deeper walkthrough with examples, our upcoming ABC analysis article will cover the math step by step.

Step 2: set count frequency by class

Once you have your ABC groups, assign a counting cadence to each. There is no single "right" frequency - it depends on your SKU count, team size, and how much variance you currently see. Here is a proven starting point:

These SKUs move fast, so errors appear fast. A weekly check keeps accuracy above 99% for the items that matter most.

Once a month is enough to catch drift before it compounds. Spread B counts across 4 weeks so no single week is overloaded.

Low-value items rarely cause urgent problems. One count per quarter still means every C item is verified at least 4 times a year.

If a C item is a critical component in a kit or assembly, promote it to B frequency regardless of its individual dollar value. A missing $0.10 screw that stops a $500 shipment is not a C-level problem.

Step 3: assign roles and responsibilities

Cycle counting breaks down when nobody owns it. Define three roles - even if one person wears multiple hats on a small team.

Performs the physical count. Counts blind (without seeing the system quantity) to avoid confirmation bias. Records what they see, not what they expect.

Compares the physical count to the system record. Investigates any variance before adjusting. Asks: was it a receiving error, a mis-pick, a label problem, or shrinkage?

Generates the weekly count list, assigns zones, reviews KPIs, and escalates recurring problems to operations leadership.

On a 3-person warehouse team, the coordinator might also be the reconciler. That is fine. What matters is that counting and reconciling are treated as separate steps, not one rushed task.

Step 4: build a sample weekly calendar

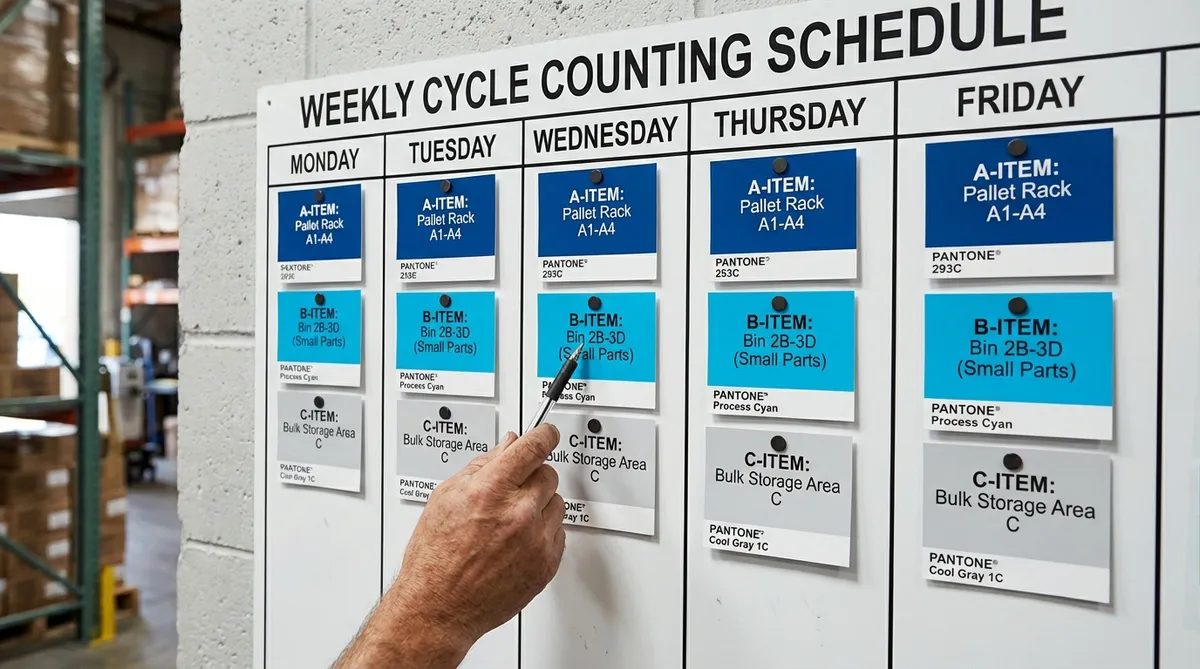

A calendar removes the decision of "what do we count today?" and replaces it with a routine. Here is a sample schedule for a team managing around 500 SKUs (100 A, 150 B, 250 C).

Count 25 A items (Zone 1). Generate the week's count list and distribute to counters.

Count 25 A items (Zone 2). Reconcile Monday's counts and log variances.

Count 25 A items (Zone 3). Reconcile Tuesday's counts.

Count 25 A items (Zone 4) plus ~38 B items (weekly slice of the monthly batch). Reconcile Wednesday's counts.

Reconcile Thursday's counts. Review weekly KPIs. Escalate any SKU with two or more variances this month.

With this rhythm, all 100 A items are counted every week, all 150 B items every month (about 38 per week), and all 250 C items every quarter (about 20 per week, added to lighter days). Adjust the numbers to fit your catalog.

Count during off-peak hours - before the morning pick wave or after the last shipment. If you must count during active operations, freeze the zone: no picks or put-aways in that aisle until the counter finishes.

Step 5: track 4 KPIs that prove progress

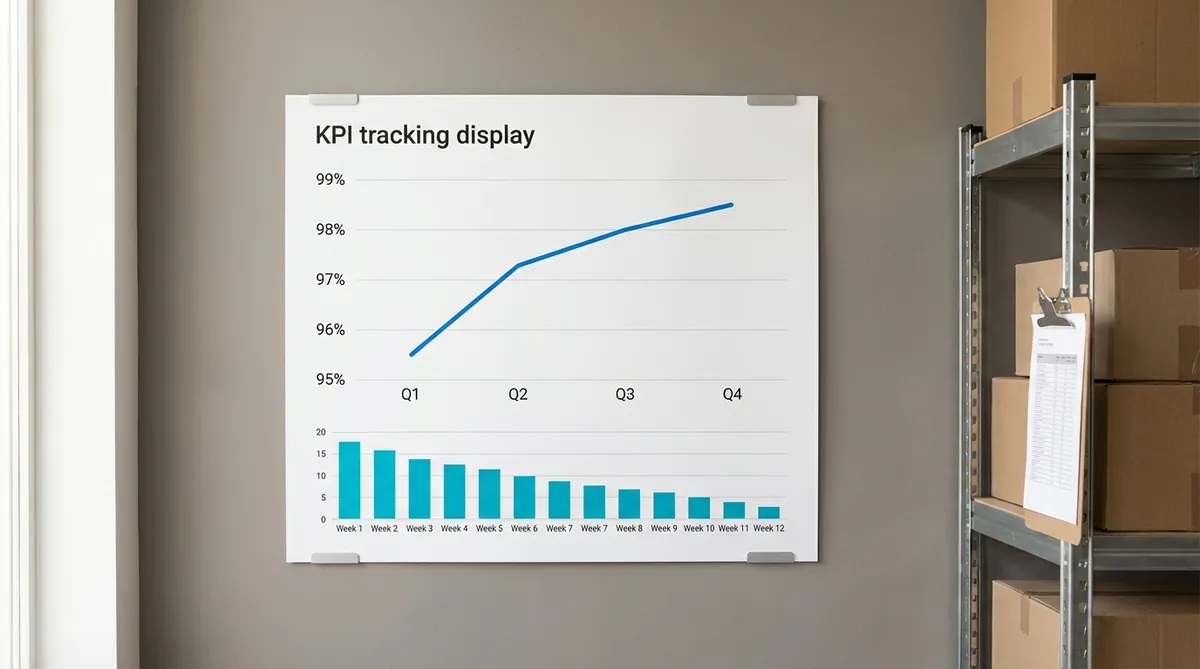

A cycle count program without KPIs is just busywork. Track these four numbers weekly and review trends monthly.

IRA = correct counts / total counts x 100. This is your headline metric. Target 97% as a baseline and push toward 99%. If IRA drops, your process has a leak - find it.

Sum the absolute dollar value of all discrepancies found this week. A high IRA with a high variance value means your errors are concentrated in expensive items - a sign your A-item frequency may be too low.

Adjustment rate = items adjusted / items counted x 100. A healthy program keeps this under 5%. Above 10% means the root causes have not been fixed, and you are just correcting symptoms.

Track unexplained losses (count < system with no process reason) as a separate line. A rising shrinkage trend is a security signal, not just an accuracy issue. Regular counting makes theft harder to hide.

Post these numbers where the team can see them. Transparency builds accountability, and a visible accuracy trend motivates the counter who found the mismatch that prevented a stockout.

Common mistakes that sabotage your schedule

- Counting without reconciling: A count that is never compared to the system record is a wasted count. Always close the loop with investigation and adjustment.

- Showing the system quantity to the counter: This introduces confirmation bias. The counter sees "48" on the screen and counts 48 even if there are really 45. Always count blind.

- Skipping counts when it gets busy: The busiest weeks are when errors happen most. If you skip counts during peak periods, you lose accuracy exactly when it matters.

- Adjusting without a reason code: Every adjustment should carry a reason: receiving error, mis-pick, damage, label swap, theft. Without reasons, you fix numbers but never fix processes. For more on investigating root causes, see our guide to inventory variances.

- Never updating your ABC classes: Products change velocity. A seasonal item might be an A in December and a C in March. Review your ABC split at least quarterly.

- Treating cycle counts as punishment: Assign counts fairly, rotate zones, and celebrate improving accuracy. If counting is always the task nobody wants, compliance will fade.

Tools that make the schedule stick

- Spreadsheet starter: A shared spreadsheet with columns for SKU, location, ABC class, scheduled date, counted quantity, system quantity, variance, and reason code is enough to start. Graduate to a WMS when volume demands it.

- Barcode scanning: Scanning a location label and then scanning items removes transcription errors. Even a phone camera can read barcodes reliably. For label setup tips, see our barcode labeling guide.

- Mobile counting apps: A phone-based tool lets counters walk the aisle, scan, and record in one step. Results sync immediately, so the reconciler can start investigating without waiting for a paper sheet.

Next step: start with one zone next Monday

You do not need to overhaul your whole operation. Pick one zone, classify its SKUs into A, B, and C, print a count sheet (or open a scanning app), and count. Reconcile Tuesday. Repeat the following Monday. Within a month you will have a rhythm, a baseline accuracy number, and enough data to expand.

Your first-week checklist

- Export and classify:Pull your SKU list, sort by 90-day value, and assign A/B/C classes.

- Pick one zone:Choose a high-traffic area with mostly A items for your first count.

- Count blind:Have a team member count without seeing system quantities. Record the results.

- Reconcile next day:Compare physical counts to the system. Investigate every variance before adjusting.

- Log your first IRA:Calculate accuracy % and post it. This is your baseline to beat.