You just scanned the last box in Aisle 4, Bin C. Your system says there should be 147 units. You counted 132. There is a 15-unit gap, and your finger hovers over the "Adjust" button. It would be so easy to just update the number and move on.

But here is the problem: adjusting the count fixes the symptom, not the disease. That missing inventory did not vanish into thin air. It was mis-picked, mis-received, mis-labeled, or mis-recorded. If you do not find out which, it will happen again. And again. And eventually, those small leaks sink the ship.

This guide teaches you how to investigate inventory variances like a detective, not a data clerk. You will learn when to dig deeper, what questions to ask, and how to turn every discrepancy into a process improvement.

Why investigation matters: symptoms vs. the disease

Most warehouse teams treat variances like typos. They correct them and forget them. But every variance is a clue. It tells you where your process is breaking.

Consider this: if the same SKU drifts by 10 units every week, you do not have an inventory problem. You have a process problem. Maybe the bin label is faded. Maybe two similar products are shelved side by side. Maybe one picker consistently grabs the wrong box. Adjusting the count weekly treats the symptom. Finding the root cause cures the disease.

Research shows that 58 percent of global retailers have inaccurate inventory due to fragmented data and outdated processes. The fix is not more counts. It is better investigations.

The variance triage: when to adjust vs. when to investigate

Not every variance deserves a forensic audit. You need a triage system that separates noise from signal.

Set tolerance thresholds

Define clear rules for what gets auto-adjusted and what gets investigated. A common framework is:

Variance ≤ 2 percent or ≤ $50 value. Accept the recount, update the system, log the reason code (e.g., damaged, found stock), and move on.

Variance > 2 percent and ≤ 5 percent, or $50 to $500 value. Trigger a second recount by a different person. If the recount confirms the variance, investigate.

Variance > 5 percent or > $500 value. Stop. Recount immediately. Review transactions. Involve a supervisor. Document everything.

Tighten these thresholds for A-items (high-value SKUs) and loosen them for C-items (low-value bulk). A 5 percent variance on a $2,000 laptop is a red flag. A 5 percent variance on $0.10 washers is statistical noise.

Always investigate any variance exceeding your dollar threshold, even if the percentage is small. A 1 percent variance on a $10,000 pallet is still a $100 loss.

The investigation playbook: 4 steps to find the truth

When a variance crosses into investigation territory, follow this workflow. Every step builds evidence.

Step 1: Recount first, ask questions second

Before you dive into transaction logs, verify the count is real. Human error is the most common cause of discrepancies.

Recount Protocol

- Use a different counter:Assign someone who did not perform the first count to eliminate confirmation bias.

- Perform a blind count:Do not tell the second counter what the system says or what the first counter found. Let them count independently.

- Check the full location:Ensure no boxes are hidden behind other stock, pushed to the back, or sitting on the floor unlabeled.

- Verify the SKU:Confirm you are counting the right product. Look-alike SKUs are a frequent culprit.

If the recount matches the original variance, you have confirmed a real discrepancy. Now the detective work begins.

Step 2: Review recent transactions

Pull the transaction history for the SKU and location. Look for clues in the last 7 to 14 days.

Transaction Review Checklist

- Receiving logs:Was the SKU recently received? Did the team verify the quantity, or did they accept the packing slip blindly?

- Picking records:Was the SKU picked for an order? Was the pick confirmed by barcode scan or manual entry?

- Transfers:Was stock moved between locations? Was the transfer recorded in both the "from" and "to" bins?

- Returns:Did a customer return this item? Was it restocked in the correct location?

- Adjustments:Has this SKU been manually adjusted recently? Who approved it, and why?

Look for timing patterns. If the variance appeared the same day as a large receipt, the root cause is likely a receiving error. If it appeared after a wave of picks, suspect a picking mistake.

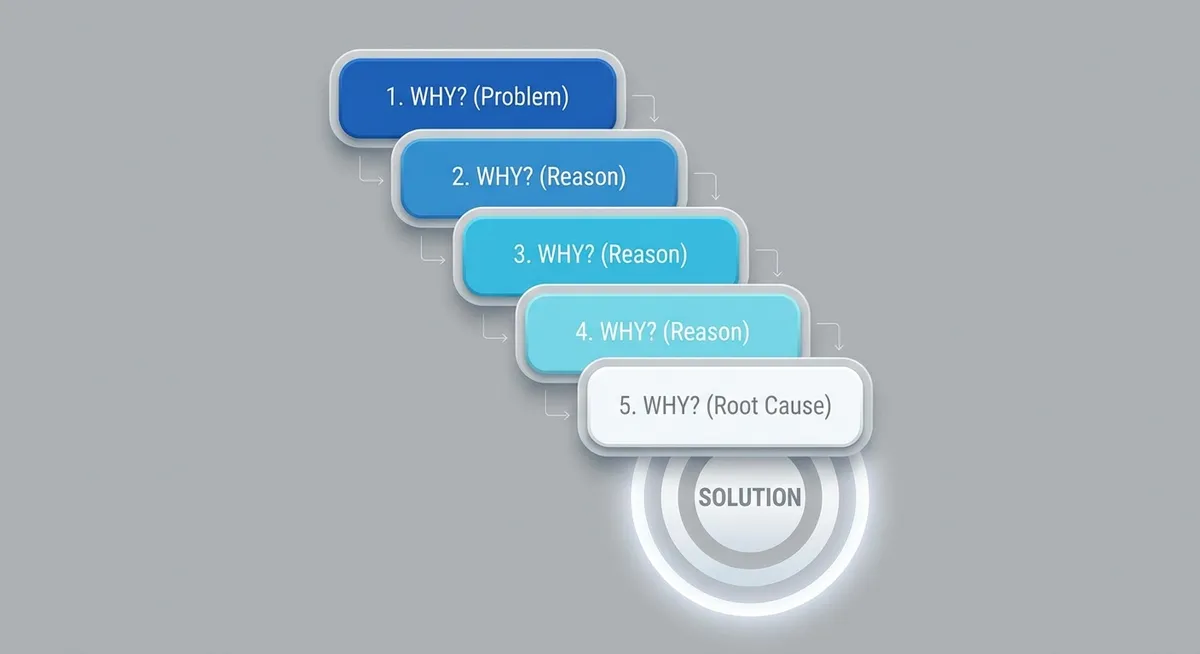

Step 3: The 5 Whys (root cause analysis)

Once you have the transaction data, drill down to the root cause using the 5 Whys technique. This method, developed by Toyota, forces you to move past surface-level explanations.

Here is a real-world example:

Why is the count off by 15 units? Because the physical count is lower than the system record. Why is the physical count lower? Because 15 units were shipped to the wrong customer. Why were they shipped to the wrong customer? Because the picker grabbed the wrong box from Bin C. Why did the picker grab the wrong box? Because two similar-looking SKUs are stored next to each other, and the bin labels are identical in size and color. Why are the bin labels identical? Because our labeling system does not visually distinguish between similar SKUs. Root Cause: Inadequate visual differentiation in bin labeling for look-alike products.

Notice how the investigation moved from what happened (wrong box shipped) to why the system allowed it to happen (poor label design). That is the power of root cause analysis.

Step 4: Document everything

Every variance investigation should create an audit trail. Future you (and your auditors) will thank you.

Documentation Requirements

- Variance details:SKU, location, expected quantity, counted quantity, variance amount, variance percentage, dollar value.

- Who and when:Name of the original counter, name of the recounter, date and time of each count.

- Root cause:A clear, one-sentence explanation of why the variance occurred (e.g., "Receiving team accepted packing slip quantity without physical verification").

- Corrective action:What you did to fix it (e.g., "Retrained receiving team on blind receipt protocol").

- Preventive action:What you changed to prevent recurrence (e.g., "Updated SOP to require barcode scan confirmation for all receipts over 50 units").

Store this documentation in your WMS or a shared variance log. It becomes the foundation for pattern recognition.

Common culprits: where to look first

Certain types of errors account for the majority of inventory variances. When you start an investigation, check these usual suspects first.

The supplier shipped 100 units, but your receiving team logged 120 because they trusted the packing slip instead of counting. Or they counted cases but entered pieces. Always verify receipts physically, especially during peak season when temps are rushing.

A picker grabbed Product A instead of Product B because they look identical, or they are slotted next to each other. Your system thinks Product B left the building, but it is still on the shelf. Use barcode scanning to eliminate manual selection errors.

Stock was put away in Bin C, but the system says Bin D. Or it was moved during cleaning and never relocated in the WMS. This creates phantom inventory (system says it's there, but it's not) and found stock (it's there, but the system does not know).

The receiving team counted 10 cases and entered 10 pieces. Or they counted eaches when the system expected pallets. UOM errors create massive variances that compound over time. Create a reference guide and enforce it.

Someone typed 150 instead of 15, or transposed digits (132 vs. 123). Manual entry is the enemy of accuracy. Automate wherever possible.

A box arrived damaged, and the team discarded it without logging the adjustment. Or a customer return was accepted but never restocked. Damage and returns need the same workflow rigor as sales.

Pattern recognition: the real detective work

Individual variances are data points. Patterns are insights. This is where you move from reactive firefighting to proactive prevention.

Look for repeating triggers

Run a variance report and filter by:

- Same SKU repeatedly off: The product itself is the problem. Is the packaging confusing? Is the barcode damaged? Is it frequently returned?

- Same location repeatedly off: The bin is the problem. Is the label faded? Is it too high or too low to see clearly? Is it in a high-traffic zone where stock gets bumped?

- Same picker repeatedly off: The person is the problem. Do they need retraining? Are they rushing? Are they new and unfamiliar with SKU locations?

- Same time of day/week: The process is the problem. Are variances spiking during shift changes? During peak order volume? When temps are working unsupervised?

If the same SKU drifts twice in a month, stop counting and start solving. Treat it as a process failure, not an inventory glitch.

If a SKU, location, or picker triggers a variance investigation twice within 30 days, escalate to a CAPA (Corrective and Preventive Action) review. Assign an owner and a due date to fix the underlying issue.

Creating a variance resolution workflow

Ad-hoc investigations fail. You need a documented workflow that every team member follows every time.

Standard Variance Resolution Workflow

- Variance detected:Cycle count or physical audit identifies a discrepancy exceeding threshold.

- Recount triggered:System or supervisor assigns a second counter for blind recount.

- Variance confirmed:If recount matches original, variance is real. If not, accept recount and close.

- Investigation opened:Supervisor reviews transaction history and assigns investigation to appropriate team (receiving, picking, etc.).

- Root cause identified:Team completes 5 Whys analysis and documents findings.

- Corrective action:Immediate fix is applied (e.g., retrain picker, relabel bin, move SKU).

- Preventive action:Process change is implemented (e.g., update SOP, add barcode scan requirement).

- Adjustment approved:Supervisor or manager reviews documentation and approves system adjustment.

- Variance closed:Adjustment is posted, and case is archived with full audit trail.

Many WMS platforms support approval workflows. Configure them to enforce this process automatically.

Turning variances into process improvements

The ultimate goal is not to get better at investigating variances. It is to stop having variances in the first place.

Use your variance log as a continuous improvement engine:

- Monthly review: Pull a report of all variances. What are the top 5 root causes? What are the top 5 SKUs? What are the top 5 locations?

- Quarterly deep dive: Bring together receiving, picking, and inventory teams. Share the data. Brainstorm fixes.

- Annual audit: Measure your variance rate year-over-year. A healthy operation should see variance frequency decrease over time as processes mature.

Every variance investigation should ask two questions:

1. What do I need to fix right now to correct this discrepancy? 2. What do I need to change permanently so this never happens again?

The first question fixes the symptom. The second question cures the disease.

Conclusion: from firefighting to prevention

Finding a variance is easy. Any decent cycle count program will surface discrepancies. But finding why it happened, and preventing it from recurring, separates world-class operations from mediocre ones.

Treat every variance as a teaching moment. Ask why. Dig deeper. Document your findings. Look for patterns. Fix the root cause, not the number.

Over time, your variance rate will drop. Your accuracy will climb. And your team will stop firefighting and start preventing. That is the goal.